WHILE Volvo plant equipment is predominantly geared towards the construction and materials-handling industries, Volvo loaders have proved very popular with Irish farmers and contractors since the 1970s, in particular the L series of loaders.

In the 70s and 80s, Volvo LM 840 and 841 ‘all-rounder’ loaders found particular favour as handlers for the sugar beet industry.

Also in the 1980s, the Clarke Michigan 35B was another popular choice for pushing up silage. Purchased by Volvo BM, the Clarke Michigan 35B and Volvo’s LM loaders put down roots of confidence and paved the way for Volvo’s L series of articulated loaders, first released in 1986.

With the ‘L’ representing loader and the number designating the turning lifting weight in tons, the Volvo BM L70 and L90 were a common sight.

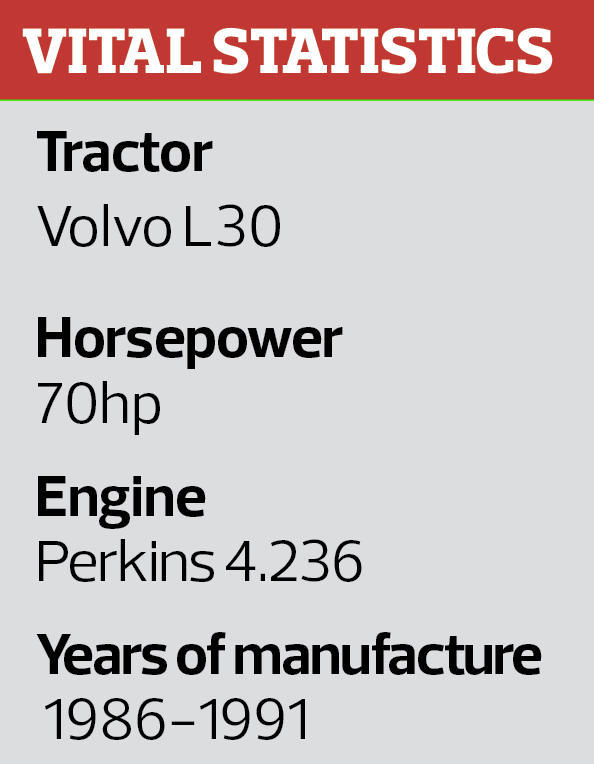

A little less common, the entry level in the series was the L30 – a six-ton loader, designed to be agile and low, yet powerful with the refinements of its larger siblings. Unique to the L30, a four-cylinder, 3.6 litre Perkins engine powers the loader which is naturally aspirated. Rated at 70hp, this is the only loader in the six-model L series line-up not to use Volvo’s own engine.

The loader is equipped with a three-speed transmission, with Hi and Lo ranges providing 6F/6R, which interestingly is manufactured by Clark, which Volvo VME group had acquired. The L30, and all other models in the initial L series line-up have a parallel arm-type loader linkage, controlled by three lever ‘lollipop’ type controls – while many other manufacturers use a joystick. Hydraulic output is a very capable 103l/min and a loading cycle time (load position, tip and back to load) of just over 11 seconds.

The L30 also benefits from the same cab as its larger siblings, which Volvo were keen to boast about the strategically placed air vents at the windows to keep the glass condensation free. Air conditioning was an optional extra with the forward opening door not suited to being open during operation, however the full window to the right of the operator could be opened fully, latched back against the cab.

Interestingly, Volvo L series loaders used the parallel arm linkage configuration until the C range of loaders were released in 1995.

These loaders were fitted with the Z type linkage. Volvo continue to use this linkage, as well as O&K, Komatsu and New Holland, with JCB retaining the parallel linkage throughout their entire production of their FarmMaster loaders.

• Contact Peter at [email protected] or see Instagram @flashphotoscork